How Do I Choose the Right Castor?

-

- Ross Castors Blog

- 8 Jul 2025

When you’re responsible for keeping your workplace running smoothly, the last thing you want is equipment that’s difficult to move, damages your floors, or slows you down. The good news? Finding the right castor is simple once you know what to look for. We’re here to guide you through the five key steps to making a confident choice.

1. Load Capacity

When choosing castors, the first thing to consider is the weight your equipment needs to carry. Getting this right means you can move your load safely and easily, without risk of damage or unexpected breakdowns.

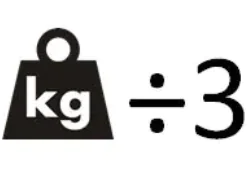

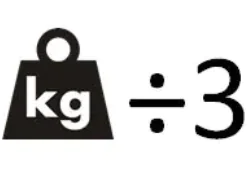

Use the following calculation to determine the maximum load each castor must carry:

Max Load per Castor = (Unit Weight + Maximum Extra Load) ÷ 3

By dividing the total load by 3, you allow for a margin of safety, accounting for uneven floor surfaces and dynamic forces that may occur during movement. This calculation ensures that each castor can handle the load effectively in a safe working environment, reducing the risk of overloading and enhancing the longevity of your equipment.

Pro Tip: Always plan for real world conditions. A little extra load capacity means less worry for you and longer life for your equipment.

2. Wheel Material: Protect Your Floors and Maximise Performance

The material of your castor wheel makes a big difference in both performance and floor protection. The best choice depends on the surfaces you work on and the loads you move.

- Rubber Castors: Quiet, gentle, and non-marking, ideal for indoor use on tiles, wood, or laminate.

- Polyurethane Castors: Tough and resistant to chemicals/abrasion; great for a range of surfaces.

- Nylon Castors: Hard, low-friction, suitable for smooth concrete or hard floors.

- Steel Castors: Ultra-durable for heavy industrial use where strength is paramount.

Shop our range of wheel materials and see which is best for your application.

3. Wheel Diameter: Smooth Movement Over Any Obstacle

The size of your castor wheels can make everyday tasks much easier. Larger wheels handle bumps, thresholds, and uneven surfaces with less effort, giving you smoother movement and better control. They also help spread the weight more evenly, which protects your floors from unnecessary wear.

However, bigger wheels do raise the height of your equipment, so if you have tight spaces or low-clearance requirements, it’s worth double checking your measurements.

4. Mounting Type: The Perfect Fit for Your Equipment

Getting the right mounting type is key to ensuring your castors are secure, stable, and easy to install. Each mounting option is designed for specific equipment and applications, so choosing the right one saves time and avoids hassle later on.

Top Plate: This type of castor features a flat metal plate that is bolted to the bottom of your unit. It provides a secure and stable attachment, making it ideal for heavier loads. Top plate castors are commonly used for equipment that requires robust support and minimal movement.

Bolt Hole: Bolt hole castors are designed with a central hole through which a bolt or screw is inserted to attach the castor to the unit. This option offers flexibility and is suitable for applications where easy installation or replacement is a priority.

Threaded Stem: These castors have a threaded stem that screws directly into a matching hole on the unit. They provide a strong connection and are often used for lighter equipment or furniture that needs to be frequently moved or adjusted.

Choosing the right castor type ensures that your equipment is securely fixed and capable of handling the expected load, contributing to both safety and functionality.

Pro Tip: Make sure the mounting type matches the design and structure of your equipment.

Top Plate

Stem Mount

Bolt Hole

5. Environment: Choose Castors That Thrive in Your Conditions

Where and how you use your castors affects their lifespan and performance. By matching your castor choice to your environment, you’ll enjoy smoother operation, less maintenance, and better value.

- Wet or humid conditions: For areas prone to moisture, we recommend stainless steel or zinc-coated castors paired with water-resistant wheels. This combination helps prevent rust and keeps your equipment moving reliably for longer.

- High temperatures: If your environment involves ovens, kilns, or other heat sources, opt for heat-resistant materials like phenolic resin or specially formulated rubber. These castors stay strong and safe, even when the temperature rises.

- Clean rooms or food processing areas: Hygiene is critical in these settings. Look for non-marking wheels and rust-proof components that are easy to clean and designed to meet strict hygiene standards.

- Outdoor use: When your equipment needs to withstand the elements, UV-resistant and weatherproof materials are essential. These options are built to handle sun, rain, and changing temperatures keeping you rolling in all conditions.

Selecting the right castor isn’t just about ticking boxes it’s about making your business safer, more efficient, and easier to manage every day. By considering load capacity, wheel material, wheel size, mounting type, and your working environment, you’re already on your way to the perfect solution.

But you don’t have to figure it out alone. At Ross Handling, we’re here to help you every step of the way, with expert advice and a full range of high quality castors to suit every application.

Contact our team and we’d be delighted to help you find exactly what you need. Or, if you’re ready to get started, explore our full selection online.

(EUR)

(EUR)